KMK NEWSLETTER

DECEMBER 2025

Retaining Bow Inspection

One of the most common causes of jams on the GSX machine comes from worn, broken and misinstalled retaining bows in the pin stations. These bows hold the pins during the machine cycle and release the pins into the pin holders at the correct time. They can become broken or worn with time, causing jams on the table.

There are 2 styles of retaining bows. One has a flap, and one does not. The bows without the flap are for the 7 and the 10 pin stations. Installing the wrong bow in the 7 and 10 positions will cause those positions to fail to double load and this can cause timeout calls.

The 7 and 10 bows, along with the number 4 position will also have a retaining bow extender installed on them. The extender will prevent the rearward traveling pins from “nose diving” into the pin station. If missing, you can replace with SM-47-862931-000 Retaining bow extender from Strike Maker.

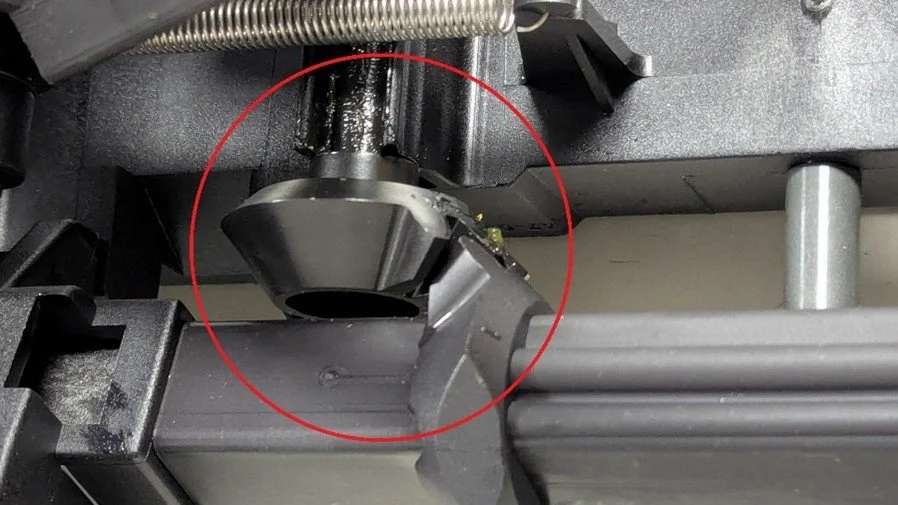

A broken retaining bow with the flap missing will most likely look like the photo below. Usually, a clue that there is a broken bow is finding the flap behind the machine. An economical alternative to the original part is the Strike Maker Part number SM-47-094779-001 Retaining Bow with Flap.

A retaining bow broken in this way in conjunction with a worn spindle retaining pin can allow a pin to fall from the pin station onto the table causing a jam. Always inspect the retaining pins for wear anytime you remove a bow. If you don’t have a replacement pin, it is possible to place the side with no wear against the plastic bearing on the square spindle. Replace this pin as soon as you can with a new one, SM-47-094789-003.

Another area to focus on when changing a retaining bow is the gear on the square spindle. The gear needs to be timed correctly to allow the pin station ejector flap to load a pin into the station. The gear timing can function if it is 1 tooth off, but the ejector flap will not lower completely. The photo below shows the correct gear timing.

With a little practice, changing a retaining bow can be done in just a few minutes. If you happen to have a complete pin station as a spare, use it to become familiar with the procedure and the parts needed to make this area of your GSX machine run smoothly.

more tips, videos, and troubleshooting

Calling all mechanics Submit your tips and tricks!

Have a suggestion for a great tip or trick to be added to our website? We welcome suggestions as we grow the information on this site. Submit your ideas below!